Replacement of Two 130′ Secondary Clarifiers at a 25 MGD Wastewater Treatment Facility

Challenge

A municipal WWTP found that (2) of their secondary clarifiers were too rusted and corroded to properly function. A traditional clarifier refurbishment consisting of sandblasting and painting was not a viable option because one of the clarifier rake arms had recently broken due to its poor condition. The plant engineers decided that a clarifier rebuild was necessary to ensure proper future operation.

Solution

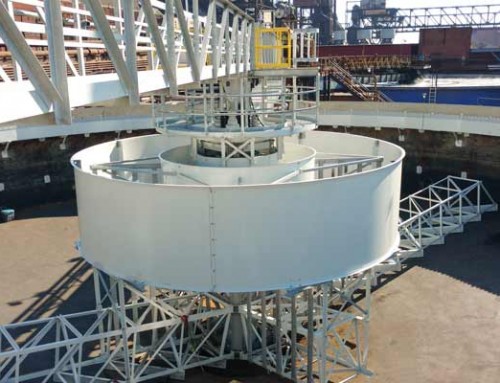

Monroe Environmental sent a team to the site to inspect the old equipment and take the necessary measurements. Monroe oversaw the removal of the clarifier internals and designed a new system to perfectly fit the existing concrete tank. Monroe’s team of shop technicians and AWS certified welders fabricated the new steel equipment and fully assembled the unit in their shop.

Each 130 ft. clarifier rake arm was fully assembled and pre-fit to simulate the angle of the existing clarifier tank floor. This ensured that on-site installation would be as fast as possible, with no field engineering or fabrication required.

After testing and alignment was completed, the new internals were shipped to site for replacement. The Monroe team oversaw the installation of the new equipment to ensure correct assembly, and the entire on-site installation process for each clarifier took only three days!

Result

Both 130 ft. clarifiers returned to full operation and are currently in use at the facility. A previous clarifier rebuild installation at the same plant with a non-Monroe clarifier took roughly one month to complete versus the three days required to install each Monroe clarifier. These rapid installations — a direct result of our shop assembly and testing — maximized clarifier uptime and allowed the plant to return to normal operating procedures faster than the competition.