The Monroe X‑Flo Mobile Clarifier™ is a patent-pending, completely integrated mobile water treatment solution for temporary job sites, emergency use, and/or bypass operations. The system can also be utilized as a stand-alone clarifier on a permanent basis. The truly unique design of the X‑Flo Cartridge allows for the removal settle-able solids as well as floating solids/oils from your wastewater & process liquids — something that cannot be achieved with other mobile treatment tanks or plate clarifier systems!

Monroe X‑Flo Mobile Clarifier Design

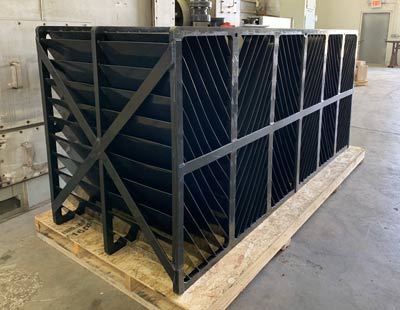

The Monroe X‑Flo Mobile Clarifier™ combines high-efficiency X-Flo Separator Plate Packs with our unique V-bottom mobile treatment tank to produce the simplest and most effective mobile clarifier available on the market. It removes settle-able solids (TSS, metals, etc.) and floating solids/oils/scum from your wastewater and process liquids — something that cannot be achieved with other plate clarifier systems. The V-bottom tank provides continuous sludge removal and eliminates the need for submersible pumps, vac trucks, or constant rotation of tanks for sludge storage.

Monroe Environmental has taken their diverse application and clarifier design experience and applied it to the mobile water treatment industry. We’ve adapted a tried-and-true clarification technology into a cutting-edge mobile clarifier that is easy to use and highly effective.

Simple Operation with No Moving Parts

Utilizing a co-current, cross-flow operation, the process stream flows horizontally through the cartridge. Heavier solids settle on the surface of the plates while lighter contaminants rise on the underside of the plates. Still water channels create a quiescent zone to prevent re-entrainment. The settled solids collect at the bottom of the tank while the floating materials are collected by a surface skimmer and are removed from the system.

Clarified liquid exits the unit through the effluent box, which consists of an effluent weir, launder, and flanged discharge. Units can achieve up to 1,000 GPM throughput at gravity flow, depending on the application.

Continuous Sludge Removal with V‑Bottom Tank + Sludge Header

The design of the X-Flo Mobile Clarifier™ eliminates the requirement for submersible pumps, vac trucks, or continual rotation/indexing of storage tanks to manage sludge removal. The continuous sludge header spans the length of the pyramid hopper and includes multiple valves for optimal control of sludge removal. A single discharge connection makes operation of external pumps quick and easy. Solids can be continuously removed from the system without calling in a vac truck or operating large, slow, and dirty submersible pumps.

Rental Clarifier for Mobile Water Treatment

Units can be deployed immediately for emergency treatment, or scheduled for planned outages, maintenance, and high-flow events such as spring snow melts or rainy seasons.

Optional pre-treatment mixers and sludge pump skids can be incorporated when required.

If you have a Clarifier or other process treatment system (clarifier, DAF, decant tank, oil/water separator, filter system, etc.) that requires maintenance, keep your plant running with the use of the Monroe X-Flo Mobile Clarifier.

Because we manufacture all types of Clarifiers, we can be a one-stop shop for Clarifier Rebuilds. We can provide:

- New clarifier mechanism and/or tank (Circular Clarifiers, Thickeners, and Lamella Plate Clarifiers)

- Temporary bypass treatment with the X-Flo Mobile Clarifier to keep plant operational

- Installation of new clarifier

Monroe is the only clarifier manufacturer that provides all of these services as a complete package.

Clarifier Rental or Purchase New

There are many ways to get the Monroe X‑Flo Mobile Clarifier technology to your job site. The complete, integrated clarifier can be sold as a stand-alone system or rented on a monthly basis.

Monroe Environmental custom designs, fabricates, and retrofits wastewater treatment equipment all the time. We are experts. Contact an Applications Engineer today to review your requirements and we’ll customize a solution for your application and needs.

The Monroe X-Flo Separator Plate Pack

The Monroe X-Flo Separator Plate Pack provides exceptional oil separation but also easily sheds solids due to larger spacing between separator plates. The Monroe X-Flo Separator Plate Pack can be constructed from corrosion resistant thermoplastics such as UHMW and Polypropylene, or stainless steel and high-grade metal alloys.

Plate packs can also be purchased for retrofit for many OWS designs. If you have problems with an existing OWS check out our blog post to learn how the X-Flo Separator Plate Pack can improve performance.