Monroe Environmental offers a variety of sludge collector designs to suit your needs, including chain and flight, hoseless suction, and many others. We have experience with many applications including water and wastewater treatment, refineries, power plants, steel mills, and other demanding applications.

Hoseless Design Improves Sludge Removal

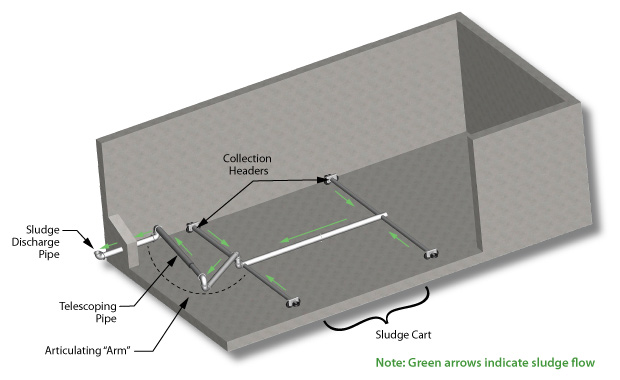

The hoseless-type collector offered by Monroe Environmental is a more efficient design for collecting settled solids from sedimentation basins versus flexible hose collectors or fixed grid collectors.

The Monroe Sludge Collector utilizes all-rigid piping which avoids the pitfalls common to flexible hose collectors such as air pocketing, ripping, collapsing, and tangling. It also more efficiently captures the fluidized sludge than fixed grid collectors and chain and flight collectors which produce lower solids concentrations and require more dewatering than those captured from the Monroe Sludge Collector.

- Reduces the distance sludge must travel to be discharged from tank

- No in-pipe baffling/interference once sludge is collected

- Reduces the chance of clogging — improves sludge flow

- Telescoping arm with UHMW bushings does not impede sludge flow through the collector

- For smaller basins, no telescoping pipe is required

The Sludge Collectors are the perfect compliment to the highly efficient Monroe Plate Settlers for potable water treatment. The unit can also be provided separately should your plant only require a more efficient settled solids removal system.

Monroe Sludge Collector installation

Monroe Hoseless Sludge Collector Design

- Hoseless, hydraulic pressure suction collector — gravity head or pump induced

- 304 stainless steel construction

- Articulating sludge discharge pipe eliminates the need for cumbersome hoses

- Orifices on collection header uniformly draw from sludge blanket

- Dual-reel positioning drive and cable system ensures smooth header movement along tank floor

- No submerged electrical components or lubricants required

- Electrical panel for automatic control with digital output and position indicators

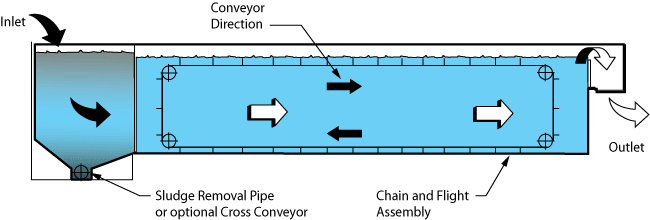

Chain and Flight Collectors

Monroe Environmental is uniquely qualified to supply chain and flight collectors for nearly any application. Monroe’s engineering team has over 40 years’ experience designing, fabricating, and operating chain and flight conveyor systems for the most demanding applications including water and wastewater treatment plants, refineries, power plants, steel mills, chemical plants, ash handling, cullet dewatering, and other heavy duty applications. Many of Monroe’s installations involve toxic liquid/solids separation under the most strenuous process conditions.

Monroe Environmental chain and flight collectors are built to the highest possible standards for quality and successful long term operation. To arrive at the optimum design for each individual application, Monroe will analyze:

- Flow rate

- Sludge loading

- Drive configuration

- Runtime

- Conveyor speed

- Torque requirements

- Flight strength

- Sprocket design

- Wear shoes

- Component supports

- Materials of construction

- Maintenance requirements

- Control requirements

- And many other parameters

Monroe Environmental offers chain and flight collectors in a variety materials including:

- Mild steel

- Stainless steel

- Specialty alloys

- Non-metallic (FRP, polymer, etc.)

Chain and flight collector with non-metallic chain, flights, wear shoes, and flight supports.

Drive and drive chain during shop testing

Chain and flight collector, coated steel construction

Alternative Sludge Collector Designs

Monroe Environmental also offers other sludge collector designs for specific applications including:

- Screw augers & mechanical agitators

- Sludge rakes

- Mud valves

- And many others