Monroe Environmental manufactures several types of water purification clarifiers, primarily intended for the process of treating groundwater or surface water for industrial use or municipal drinking applications. Various designs exist depending on process requirements, however Solids Contact Clarifiers are the most common design for softening, turbidity reduction, metals removal, flocculation, sedimentation, and related functions. They may also be referred to as reactor clarifiers or flocculating clarifiers in some cases.

Solids Contact/Reactor Clarifiers

Large industrial plants such as refineries and petrochemical plants use Solids Contact Clarifiers as a key step in creating process water that can be used throughout the plant as a general process or cooling water.

Municipal drinking water plants use Solids Contact Clarifiers to replace conventional flocculation and sedimentation basins thus reducing footprint.

For both of these operations, surface water is drawn from a lake or river and chemically treated within the clarifier to settle solids, remove metals, reduce turbidity, and reduce hardness. Depending on the final use of the water, downstream treatment processes such as sand/carbon filtration, membrane filtration, or disinfection may be used for further treatment.

Solids Contact Clarifiers Design & Operation

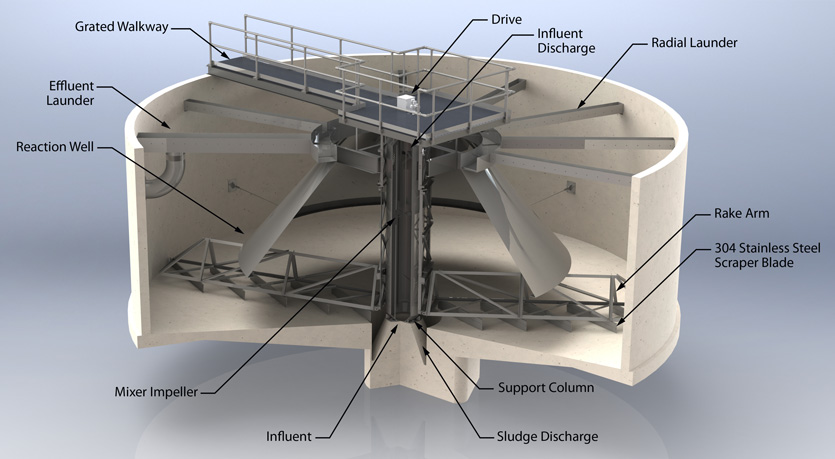

Solids Contact Clarifiers combine the functions of chemical treatment, mixing, flocculation, and sedimentation.

- Applications include lime softening, colorant removal, removal of magnesium and iron, and many others.

- The Solids Contact Clarifier employs several radial collection and outlet launders.

- The treatment chemicals are added to the influent. A mechanical flocculating well provides sludge recycling, combining previously settled precipitates from the tank bottom with the treated influent. Flow then proceeds downward out of the central well and outward to the clarification zone where flocculated particles settle. The settled particulate is then raked inward to be re-circulated, but some is discarded by the sludge pump to maintain steady conditions.

- The clean water effluent flows out through the radial outlet launders.

Coagulating & Flocculating Clarifiers

Some Flocculating Clarifiers do not need the very large reaction well (apron) common to Solids Contact Clarifiers, and may incorporate a series of mechanical mixers in the feed well to achieve the process objectives.

These clarifiers have an enlarged feedwell and provide efficient mechanical flocculation. This may be combined with the addition of chemical flocculating agents. Floating matter will be skimmed off the surface and sinking matter will be raked off the tank bottom.