Monroe Environmental is the leading source for API Separator design, engineering, and manufacturing services. A well-designed, properly functioning API Separator is a tremendous piece of wastewater process equipment for refineries, chemical plants, power plants, and many other heavy-duty industrial facilities. Unfortunately, the API Separator has earned a bad reputation among plant personnel and operators due to common engineering and design mistakes that can be avoided. Monroe Environmental understands the shortfalls common with competitive API Separator designs, and continues to lead the way with innovative engineering and continuous design improvements.

API Oil/Water Separator Systems, Services, & Solutions

Monroe Environmental is a leader in API Separator engineering, design, equipment, and operation. We have a variety of systems, services, and solutions that your plant can utilize to improve process, efficiency, and maintenance of your API Separators and other wastewater treatment operations.

New API Separators

- Engineering and design

- Fabrication and installation

- Start-up and commissioning

Retrofit and Upgrade Existing Systems

- Drag conveyor tensioning systems

- Skimming system improvements

- Inlet diffusion systems

- Solids collection and removal

- Covers and VOC containment

- Enhanced separation and throughput

Engineering and Design

- Performance and maintenance evaluations

- Technical analysis and data collection

- Treatability studies

- Reports and recommendations

- Service and engineering contracts

- Cost estimating and budgeting

- System sizing, schematics, and design engineering

Customized for Your Specific Need and Site

- Turnkey projects

- Analysis

- Recommendations

- Fabrication

- Installation

- Customized improvement plans by site or unit process

- Maintenance and total cost of ownership reduction plans

API Standards with Customized Features

A proper understanding of influent characteristics, skimming system design, drag conveyor torque requirements, component selection, sludge conveyance, and maintenance procedures is required to engineer and fabricate an API Separator that will last for years.

Monroe Environmental will consult with plant engineers and operators to get a thorough understanding of their concerns and design requirements, then custom design an API Separator that will adequately meet those needs – which we know are unique to the plant.

API Separator completely assembled in Monroe shop

Designed Per American Petroleum Institute Standards

Monroe Environmental API Oil/Water separators are designed per American Petroleum Institute standards (API) for above and below ground installations. The Monroe API Separator is designed for the removal of free oil and solids. If the removal of soluble substances is required, Monroe can provide additional treatment equipment or will recommend other Monroe Clarifiers.

API Separator Theory

Gravity differential settling is used to separate the oil from water. Monroe engineers will evaluate the type and state of the oil and the characteristics of the waste stream to determine the proper design and size of the separator. Oil globule size, specific gravity of the oil and wastewater, temperature, and viscosity should be considered. Suspended solids will also be settled from the wastewater and provisions of this will be part of the design.

API Separator Design

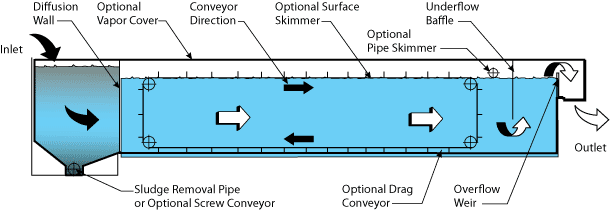

The basic components of the Monroe API Separator include an inlet section with diffusion wall, separator channel, an oil retention baffle and an outlet section. Depending on your requirements, additional options can include trash screens, a slotted pipe skimmer, surface conveyors, and a bottom drag or screw conveyor for solids handling.

Complete covers of various materials are available including the necessary environmental and safety requirements. These provisions may include a nitrogen blanketing system, carbon filtering to remove hydrocarbons from the blanket gas, exhaust flares, pressure relieving valves, and access doors.

Above ground Separators are normally constructed from carbon steel with corrosion resistant coatings. Below ground Separators are normally fabricated from steel or concrete and may include the additional requirements for containment and leak detection.

Drag conveyor for solids handling

API 421 Design Specifications

Monroe Environmental utilizes API 421 design specifications while incorporating the latest technological improvements to maximize performance and efficiency for each oil water separation application. In many cases, we also custom design specialty oil water separators with process features and site specific configurations to suit your needs. We are clarification and separation experts, and you can count on our experience, quality of fabrication, and ongoing support to ensure you have a successful system over the long term.

Circular Separators

Monroe Environmental also provides Circular Oil Water Separators that can take the place of rectangular API Separators in some cases. These units are equipped with enhanced oil skimming mechanisms, high torque drives, and sludge collection rakes for handling the heaviest oil and solids loading applications.

A Monroe Environmental Applications Engineer can best advise on the pros and cons of each system design based on your project’s specific requirements.

- API Separator on legs

- Installation at refinery

- Insulated API Separator

- Non-metallic construction

- Circular Separator

Recent Projects

API Separator Applications

Resources & Literature

Recent Case Studies

Water | API Separator for FOG Removal

Monroe engineers were able to help one of the largest potato and corn chip producers in the world meet a strict deadline to achieve lower levels of FOG in their effluent discharge.

Water | Parallel Plate Modules in Existing API Separator

Monroe Environmental increased oil & solids removal in an existing API Separator by retrofitting with parallel plate modules.