The Monroe Compact Mist Collectors are the latest advancement in performance and design from Monroe Environmental – the world-class leader in mist collection technologies. The CMC™, Compact Fiber Bed, and Compact Spiral Tube Mist Collectors are designed to meet the most demanding ergonomic, service, and performance standards of 21st century production plants. The units can be integrated into any machining operation or can stand alone to exhaust operations using straight oil or water soluble, synthetic, or mineral cutting fluids.

High Performance Capabilities – Small Footprint

Monroe Compact Mist Collectors are available in capacities from 500 CFM up to 2,000 CFM, and may be integrated into existing ductwork and ventilation systems. Optional items and controls can be added to meet the specific site requirements of your unique plant.

Higher Collection Efficiency

The Monroe Compact Mist Collectors, with longer operating cycles and higher collection efficiency, outperform other collectors. Because of slower internal velocities through the collector, filter replacement and maintenance labor costs are reduced. Collected mist and solids are continuously drained from the media without shut-down, significantly prolonging filter life and lowering overall operating costs.

Special Features

- Mild steel is standard for most installations, but special construction materials and coatings are available to meet specific applications. Solid welded seams and built-in lifting hooks provide rugged durability.

- Large, easy to open access door, with air-tight seals for servicing filters and collector interior.

- An AMCA rated fan on the outlet side of the collector with either a direct coupled motor.

- Quiet operation. Sound attenuators and fan enclosures are available to meet 77dBA and lower.

- Integral pressure gauges are available to indicate when filter maintenance is required.

- Complete electrical controls to meet customer requirements are available.

- Stainless steel construction is available for high temperature washer and other corrosive applications.

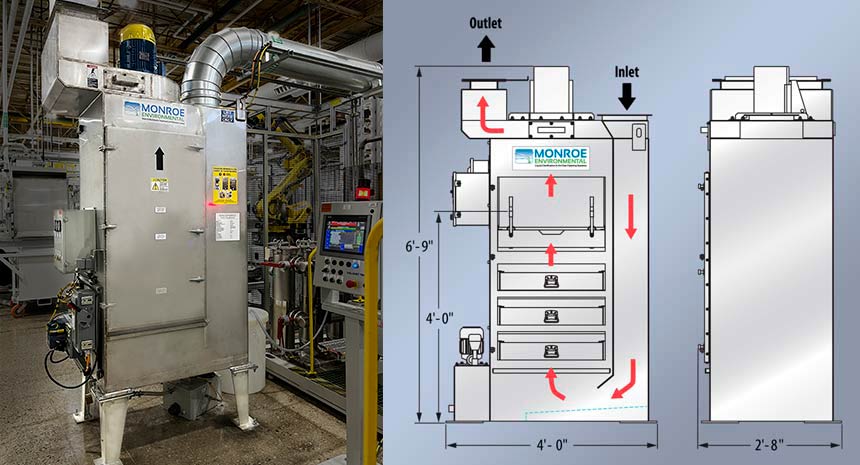

Stainless steel Compact Mist Collector for high temperature washer applications.

Many Configurations Available

Monroe Compact Mist Collectors are available in various configurations to meet your needs. Units can seamlessly integrate into any machining booth or be suspended from the building steel or other supporting structures to conserve floor space.

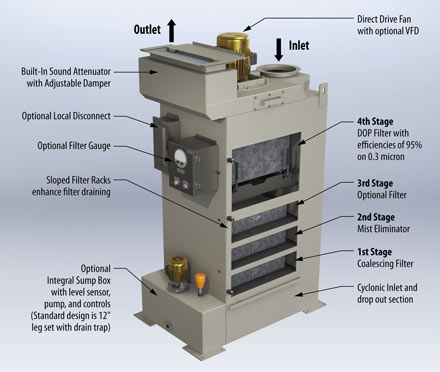

CMC™ Multiple Stage Mist Collector

The installation of a Monroe CMC Mist Collector allows you to discharge clean, filtered air back into the work area, reducing climate control costs and improving worker safety.

- Efficient four-stage design

- Low pressure drop and energy requirement

- Typical filter media life in excess of 4,500 hours or more, even under heavy inlet loading

- Small footprint

- Low height requirement

- Continuous draining during operation

- Low maintenance

- Lightweight, easy to remove filters

- Machine mounting capabilities

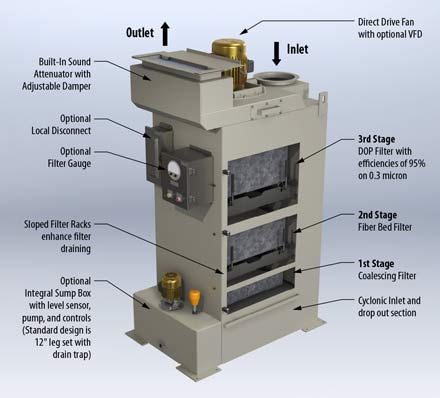

Compact Fiber Bed Mist Collector

The Monroe Compact Fiber Bed Mist Collector is a custom designed unit consisting of a continuous-duty, aerosol coalescing filter, fan assembly and, when needed, an optional pre-filter stage. Mist is coalesced in a deep box filter consisting of micro-fine fibers. These long-life filters can provide years of service before replacement is necessary depending on the application.

When the mist quantity is high and/or dust particles are present, pre-filtering is provided by separate filters. The Monroe Compact Fiber Bed Mist Collector is available in capacities from 500 CFM up to 2,000 CFM in a single unit and may be integrated with existing duct work.

- Fiber bed filtration

- Oil, mist, smoke and vapor

- Efficiencies to 99.5% by weight for < 3 microns

- Efficient multi-stage design

- Low pressure drop and energy requirement

- Small footprint, low height requirement

- Continuous draining during operation

- Low maintenance

- Lightweight, easy to remove filters

- Machine mounting capabilities

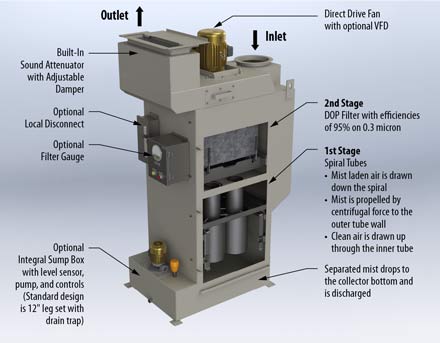

Compact Spiral Tube Mist Collector

The unit can be integrated into any machining operation or can stand alone to exhaust operations using water soluble, synthetic, or mineral cutting fluids.

- Mist, smoke and vapor removal

- Capacities from 500 to 1,200 CFM

- Low energy requirement

- Continuous draining during operation

- Low maintenance

- Machine mounting capabilities

- Welded construction