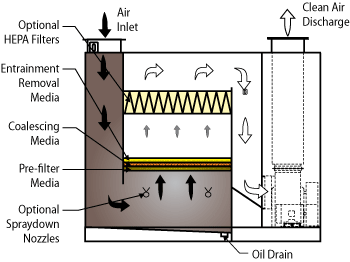

The Monroe Coalescing Oil Mist Collector is designed to collect and remove airborne oil mist, smoke and sub-micron vapors generated by operations such as high production machining and cold forming. It is a multiple stage collector that has proven capabilities exceeding 99% efficiency on many installations.

After installation of a Monroe Coalescing Oil Mist Collector, high production machining areas using water soluble, synthetic or mineral coolants can discharge clean, filtered air back into the work area, reducing climate control costs.

Broad Range of Industrial Capacities

The Monroe Coalescing Oil Mist Collector is available in capacities from 500 CFM to over 80,000 CFM in a single unit, and may be integrated with existing ductwork and ventilation systems.

Coalescing Oil Mist Collectors: The Monroe Advantage

The Monroe Coalescing Oil Mist Collector design provides the following advantages and benefits:

Designed for Minimum Maintenance

The Monroe Coalescing Oil Mist Collector is designed for continuous draining during operation, resulting in typical filter media life of 4,500 hours or more, even under heavy inlet loading.

Design Leadership

The Monroe Coalescing Oil Mist Collector, with longer operating cycles and higher collection efficiency, outperforms all other collectors. Because of slower internal velocities through the collector, medial replacement and maintenance labor costs are reduced. Collected oil mist and solids are continuously drained from the media without shut-down, significantly prolonging filter life and lowering overall operating costs.

Many Configurations Available

Monroe Coalescing Oil Mist Collectors are available in various configurations to meet your needs. Units can be suspended from the ceiling or other supporting structures to conserve floor space.