Vertical Plate Clarifier Removes Mercury and Humic Acid from Incoming Groundwater

Challenge

A company that produces industrial testing and measurement equipment needed to remove mercury and suspended solids from their groundwater prior to VOC treatment. The application was especially difficult due to very low pH and the fact that there were very fine humic solids in the liquid to be removed – solids so small they can be difficult to detect as TSS when running lab tests.

Solution

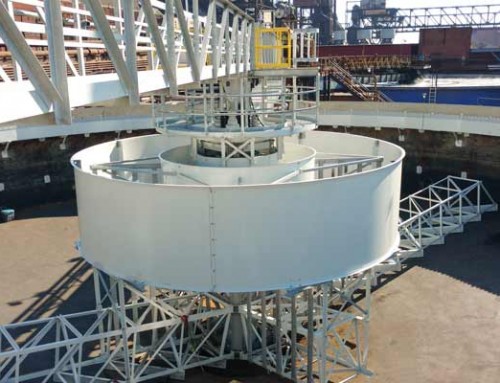

Monroe designed and fabricated a custom FRP Vertical Inclined Plate Clarifier to clean up the liquid stream. FRP construction was selected to withstand corrosion from the highly acidic water, and a conservative hydraulic loading rate was selected to allow for proper settling of the tricky solids. Material thicknesses and structural design were carefully engineered to ensure the FRP tankage would have adequate strength to support the clarifier internals and liquid volume.

Monroe also provided its expertise in field erection/assembly to the site’s installing contractor, assisting with some challenging rigging requirements. The Vertical Clarifier needed to be installed in a pre-built canvas building with entry and height restrictions, and the contractor was having difficulty figuring out how to properly rig, move, and set the unit. Monroe’s field engineer (who was contracted for supervision only), saved the day by working up a custom rigging plan and directing the installer to get the clarifier into place. Monroe also provided custom hardware that ended up being needed for the special rig but had not been planned for by the installer.

Result

Thanks to the experience and ingenuity of Monroe Environmental’s field engineer, the site was able to turn what could have been a nightmare installation into a complete success!

The custom designed Monroe Clarifier is successfully taking in a stream that looks like a strong brew of iced tea and discharging a stream that is crystal clear.

After the project was complete the customer sent a special thank you to Monroe Environmental and to Larry, Monroe’s field engineer, for a job well done!