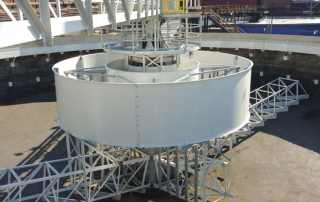

Horizontal Clarifiers for Coal-Fired Plant Stormwater

A coal fired power plant and its engineers turned to Monroe Environmental for emergency implementation of a stormwater treatment system upgrade.

Clarifier Drive Torque: Operating Use of Torque

Normally a clarifier runs at one torque value for 90 – 98% of the time. The drive unit should be designed for this running torque and should protect from excessive loads that would require it to run above its design requirements. Optimum ratings for running, alarm, and shut-off should be specified for a clarifier drive unit based on the intended use of the clarifier.

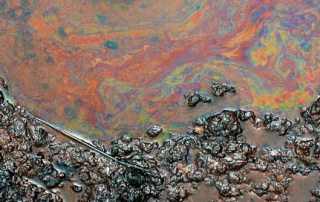

HELP! My Oil/Water Separator (or CPI Separator) is Constantly Clogging!

CPI Separators are susceptible to frequent clogging. The Monroe X-Flo Separator Plate Pack provides exceptional oil separation but also easily sheds solids due to larger spacing between separator plates.

Monroe Ships X-Flo Mobile Clarifier™ LT in 2 Days for Emergency Clarifier Bypass at Food Processing Plant

A temporary solution was needed to bypass a Secondary Clarifier while the repairs were being made. The customer contacted Monroe, and a unit was available from Monroe’s inventory to ship right away.

Design Considerations for Basin Collection Troughs in Water or Wastewater Treatment Plants

Design of the various collection troughs have a direct bearing on both the process and the economic aspects of the water or wastewater treatment facility.

Importance of Side Water Depth in Planning and Evaluating Clarification Equipment

Side Water Depth (SWD) is critical when the design engineer is planning new clarification equipment or evaluating existing units. The application of the clarifier/settling tank has a lot to do with the selection of the side water depth.