Monroe Environmental has extensive experience with explosive dust collection. We offer both wet and dry collection solutions depending on your specific application. Our wet collectors suppress and neutralize the explosive qualities of the dust, rendering them non-combustible. Monroe dry collectors utilize the latest NFPA approved explosion protection components to both prevent explosions and minimize their effects.

Selecting the Best Combustible Dust Collection Equipment

Several factors must be taken into account before selecting the best explosive dust collection method. Both wet and dry systems can be utilized depending on the physical properties of the dust such as particle size, moisture content, ignition potential, and dust concentrations. The Kst and Pmax values of a particular dust helps to classify the severity of an explosion should it occur. The higher the Kst value, the more severe the explosion.

Wet Collection Systems

In general, wet collection systems suppress and neutralize the dust’s explosive properties so that it no longer poses an explosion threat. Additionally, wet systems can better handle highly abrasive dusts that may tear, shred, and damage dry filter media. However, by design these wet systems consume fresh water and generate wastewater that must be treated, impacting the operating cost of the units.

12,000 CFM Cartridge MQL Collector in automotive plant

Dry Collection Systems

On the other hand, dry collection systems are designed not only to prevent explosions, but to contain and minimize the dangerous effects of explosions should they occur. Dry collectors are often required to have several mechanical instruments and fire suppression components such as explosion vents, spark arrestors, backdraft dampers, smoke detectors, and emergency sprinkler systems which can significantly impact the cost of the unit.

Wet or Dry Collection?

In general, the following application and site data should be taken into account at a minimum when determining the best solution for combustible dust collection:

- Process to be exhausted

- Physical properties of the dust

- Particle size, shape, and concentration

- Moisture content

- Ignition sources/potential

- Kst and Pmax values

- Site layout, ductwork, and enclosure/hood design

- Water sources

- Wastewater treatment/disposal capabilities

- Worker exposure and safety

Contact a Monroe Environmental Applications Engineer today to discuss your requirements and let us help determine which system is best for your explosive dust application.

Wet Dust Collectors for Explosive Dust

Dual Throat Venturi Scrubber – Wet Dust Collector

The Monroe Dual Throat Venturi Scrubber is a wet type dust collector that provides efficient collection and suppression of explosive dusts for a variety of applications. It is designed to provide continuous-duty collection and removal of airborne dust and particulate matter produced by manufacturing and processing operations at 99+% efficiency on many installations.

The Dual Throat Venturi Scrubber contacts the dust with water to reduce its explosion potential and transfer the particulate into the water stream. The water droplets and particulates are then removed from the air stream through separation, baffling, and mist elimination stages. This unit is excellent for explosive dust applications.

Dry Dust Collector with Fire & Explosion Suppression Options

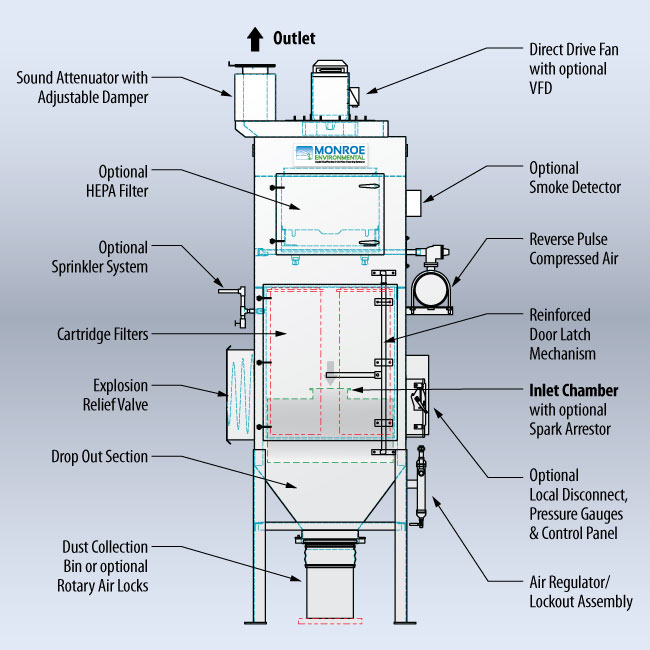

Monroe Environmental Dry Dust Collectors can be fitted with a wide variety of state-of-the-art fire and explosion suppression options to maximize worker safety and minimize equipment damage.

- Backdraft damper – NFPA 69-2014 compliant

- Explosion relief valve – resealing pressure relief valve with opening detection

- Spark detection sensor – ductwork mounted single-infrared (IR) spark/flame detection sensor

- Spark arrestor – inline ductwork spark arrestor to smother and quench sparks and embers

- Smoke detector

- Sprinkler system with flow switch

- Inlet/outlet chemical suppression

- Flame retardant filters

- Spark resistant fan

- Explosion proof motor