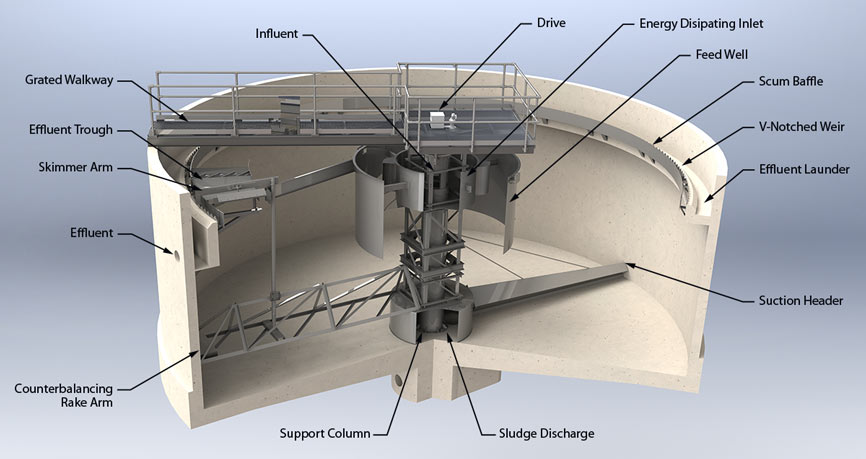

Monroe Environmental’s Secondary Circular Clarifiers for wastewater are designed to provide a high quality effluent suitable for discharge to the environment or further treatment. The Monroe Environmental Secondary Clarifier effectively separates the biological floc and colloidal solids to produce wastewater with very low levels of organic material and suspended matter.

Secondary Clarifier Influent

- Typically the influent will be mixed liquor from an aeration tank incorporating an activated sludge process. Microorganisms metabolize the biological waste that exists after primary clarification.

- A central energy-dissipating inlet (EDI) can be used, or Monroe Environmental will design a peripheral feed system that distributes influent around the perimeter of the tank, and aids in activated sludge secondary settling.

- Monroe is able to furnish a variety of EDI designs depending on customer requirements and influent characteristics.

- Mechanical flocculation and chemical treatment are available.

- An enlarged flocculation zone can be designed which allows mixed liquor suspended solids (MLSS) that are broken up during transport from the aeration basin to recombine. The larger floc that results will settle more effectively.

Drives and Sludge Collection

- Typically a radial tube header with orifices and manifold employing hydraulic suction will be designed to remove all settled solids from the tank and return them either to the head of the activated sludge process (Return Activated Sludge) or to further solid waste treatment (Waste Activated Sludge).

- Proper design of the suction header (header geometry as well as orifice placement and sizing) is critical to the successful operation of the clarifier. Monroe engineers will carefully design each mechanism to ensure constant velocities and uniform pick up throughout the clarifier.

- Alternatively, depending on the application, Monroe Environmental will design a riser pipe mechanism that uses hydraulic suction to effectively remove settled solids. As with suction headers, careful consideration must be given to the design of the riser pipes to ensure even collection of the settled sludge during operation.

- Spiral scrapers or standard scraping mechanisms can also be furnished for secondary clarification.

- Drives are carefully selected to assure durability and long life. Monroe offers both cast iron worm gear and fabricated steel precision gear drive assemblies.

Skimming and Scum Removal

- Monroe Environmental can provide a traditional skimming arm with scum beach and sludge box at the tank periphery, a full-radius scum trough, or a ducking skimmer to remove floating material.

- Anti-rotational scum baffles can be furnished depending on scum loadings.

- The unique design of the Monroe 3-axis pivoting scum wiper blade ensures constant contact with the scum beach, providing the highest removal efficiency possible.

Clarifier Effluent

- Monroe Environmental’s custom designed scum baffles and V-notch weirs will assure a high quality effluent — preventing floating material from reaching the effluent launder and providing laminar flow throughout the clarifier.

- Weirs, baffles, and launders can be furnished in a variety of materials including stainless steel, FRP, aluminum, and galvanized steel.

- Density current (Stamford) baffles and launder covers are available when required.

- Monroe will evaluate existing clarifiers to determine optimal design parameters in order to maximize effluent quality.

Recent Projects

Resources & Literature

Recent Case Studies

Water | Secondary Clarifier Rebuild Featuring X‑Flo Mobile Clarifier for Emergency Bypass

With Monroe’s X‑Flo Mobile Clarifier™, a permanent clarifier upgrade/replacement can be done at any time while keeping the plant treating water throughout the whole process.

Water | Rebuild of Two 130' Secondary Clarifiers

Monroe's Clarifier rebuild maximized clarifier uptime with rapid installation and allowed the plant to return to normal operating procedures after 3 days.