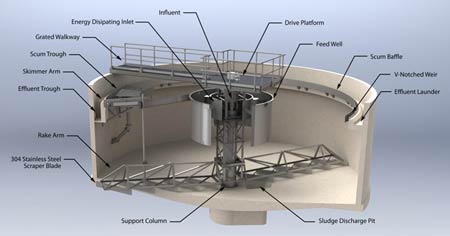

Monroe Circular Clarifiers use widely accepted settling technology based on the density difference between water and suspended solids. Monroe Circular Clarifiers and Thickeners are designed to give you the performance you require with long-term reliability. Monroe Environmental realizes that all waste streams are not alike and in many cases standard designs must be modified. Tank sizing, influent and effluent arrangements, flocculation requirements, sludge removal, and skimming methods and mechanisms are some of the considerations necessary for a successful installation.

Circular Clarifier and Thickener Expertise

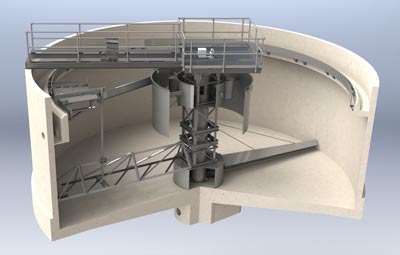

The Monroe Circular Clarifiers and Thickeners are available in self-supporting prefabricated steel units or they can be designed for installation in a concrete tank. Existing structures and systems can sometimes be utilized and upgraded for cost savings.

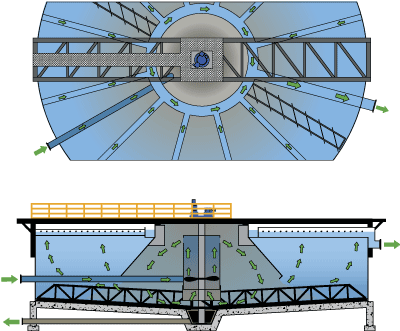

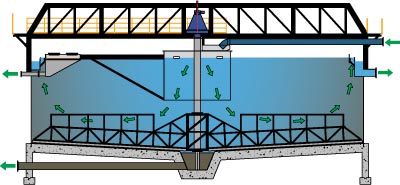

Circular Clarifiers normally utilize a center feed inlet well or a peripheral inlet. The center feed well design can be equipped with a chemical addition system with mixing and flocculation. With the center feed well, the effluent is discharged along the outer wall of the clarifier tank. Clarifiers with peripheral inlets will be designed with a center bottom liquid outlet.

Circular Clarifiers Engineered to Meet Your Needs

- Customized designs for municipal and industrial applications

- Tank diameter 10 to 250 feet

- Full and half-bridge designs

- Steel or concrete tanks

- Chemical feed system available

- Flocculator available when required

- Energy Dissipating Inlet (EDI) designs available

- MEDIC

- LA-EDI

- Alternate designs

- Thickener mechanism available

- Sludge removal configurations

- Scraper

- Spiral scraper

- Suction header

- Riser pipe

- Skimmer mechanisms

- Corrosion resistant materials and coatings

- Epoxy coated steel

- Stainless steel

- Galvanization

- Custom built replacement parts for all manufacturers

- Clarifier rebuilds

Primary, Secondary (Final), Clean Water Treatment, & Thickeners

Primary Wastewater Treatment Circular Clarifiers

Monroe Environmental’s Primary Circular Clarifiers are designed to receive raw wastewater after it has been pre-screened to remove large objects and grit. This primary sedimentation tank will produce a homogeneous liquid capable of being treated biologically and a sludge that can be separately treated or processed.Secondary (Final) Wastewater Treatment Circular Clarifiers

Monroe Environmental’s Secondary Circular Clarifiers for wastewater are designed to provide a high quality effluent suitable for discharge to the environment or further treatment.

The Monroe Environmental Secondary Clarifier (often called ‘final clarifier’) effectively separates the biological floc and colloidal solids to produce wastewater with very low levels of organic material and suspended matter.

Solids Contact and Clean Water Treatment Circular Clarifiers

Monroe Environmental manufactures several types of water treatment clarifiers that combine chemical treatment, flocculation, and sedimentation. These units are heavily utilized in both industrial and municipal processes for treating groundwater, surface water, and process water, and include Flocculating Clarifiers and Solids Contact Clarifiers.Thickeners

Monroe Environmental Circular Thickeners are a crucial step between upstream process clarifiers/separators and downstream de-watering and sludge conditioning processes. A well designed thickener provides storage and equalization, and reduces the costs associated with de-watering. Thickeners are similar to other circular clarifiers in appearance and operation, but typically require higher operating torque and alternate sludge collection designs for optimal performance.Sludge Removal Designs

Scraper

Monroe Environmental’s Primary Circular Clarifiers are designed to receive raw wastewater after it has been pre-screened to remove large objects and grit. This primary sedimentation tank will produce a homogeneous liquid capable of being treated biologically and a sludge that can be separately treated or processed.Spiral Scraper

Spiral Scraper type clarifiers utilize long-sweeping, curved scraper blades to move solids across a basin floor. They are similar to scraper-type clarifiers in that they drag settled solids to the collection area, however, they can more quickly remove these solids and thus maintain lower sludge blankets in some applications. This design can be utilized in primary, secondary, and industrial wastewater applications.

Riser Pipe

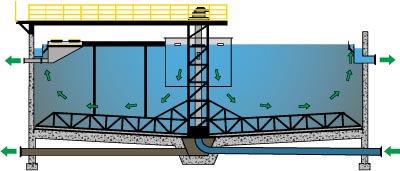

Riser pipe clarifiers rely on differential head pressure to collect settled solids from the tank floor. Each riser pipe is situated at the intersection of a v-plow and receives a continuous feed of sludge that returns to a sludge collection box near the center of the clarifier. This design is intended for secondary, biological, or flocculated solids which are more fluidized and have lower densities than primary wastewater and heavy industrial sludge.Suction Header

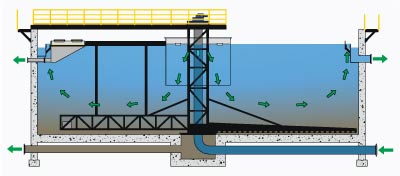

Suction header clarifiers rely on differential head pressure to collect settled solids from the tank floor. These units have a long, tapered collection arm with multiple orifices sized to stabilize and maintain optimum sludge transfer velocities through the header. This design is intended for secondary, biological, or flocculated solids which are more fluidized and have lower densities than primary wastewater and heavy industrial sludge.- High rate Solids Contact Clarifier

- Shop assembled Thickener

- Clarifier/Thickener at steel mill

- Clarifier during install WWTP

- Secondary Clarifier WWTP

- 250 ft. Spiral Scraper Clarifier

- Scraper type clarifier rebuild

- Solids Contact Clarifier WTP

- Clarifier in Monroe shop

- Thickener on legs

Recent Projects

Water & Wastewater Applications

Resources & Literature

Water | Circular Clarifier for Steel Mill Upgrade

Monroe Environmental saves steel mill $145,000 on clarifier rebuild/retrofit for blast furnace wastewater and meets stringent performance requirements.

Water | Detroit Wastewater Treatment Plant

Monroe Clarifier rebuilds replace internal components and convert sludge rakes to higher efficiency spiral scrapers at City of Detroit WWTP.

Water | Rebuild of Two 130' Secondary Clarifiers

Monroe's Clarifier rebuild maximized clarifier uptime with rapid installation and allowed the plant to return to normal operating procedures after 3 days.