Many different industries can prevent water pollution by recovering oily waste with a Monroe Oil Skimmer. The Monroe Oil Skimmer operates unattended in any area of tranquil oil accumulation. It will continuously recover floating oil in a condition that permits disposal or reclamation for other industrial purposes. Even the lightest oils from food processing can be easily removed.

Superior Belt Type Oil Skimmer

- Removes tramp oil from process liquids

- Prevents oil pollution

- Recovers valuable oil products

- Minimum maintenance

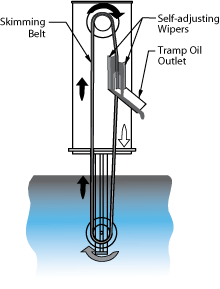

The Monroe Oil Skimmer is heavily constructed for industrial applications and consists of an endless belt, an electric motor and drive unit and a complete enclosure. The belt is suspended from a pulley, with the lower portion immersed in an oil supporting liquid. As the belt descends into the liquid, the floating oil adheres to both sides of the belt. Self-adjusting wipers mounted in a staggered position wipe the oil from the belt. The recovered oil drains into a trough for deposit into a storage tank or containers.

Why buy some rinky-dink skimmer that will last one year, and then need to be replaced? Buy an oil skimmer that will last 30 years! — The Monroe Oil Skimmer

Monroe Oil Skimmers are available in 8 in. to 24 in. belt widths

Successful Oil Skimmer Installations

The Monroe belt-type Oil Recovery Unit is designed to outlast your plant or operation. This installation at a coal-fired power plant has been in operation for over 30 years! The companies below are just a small sample of the hundreds of successful installations of Monroe Oil Skimmers.

- American Axle

- Delta Faucet

- DTE Energy

- Durr Industries

- Ford

- General Motors

- Koch Foods

- Mazda

- Owens Corning

- Owens Illinois

- Pitney Bowes

- Standard Oil

- US Air Force

- US Steel Corp.

- Whirlpool

- And many others

Oil Skimmer Product Features

Oil Skimmer Applications

Resources & Literature

Recent Case Studies

Water | Oil Recovery Unit for DTE

Monroe belt skimmer retrofit for oil reclamation from underground wastewater holding tanks at America’s 2nd largest coal-fired power plant.